Home | About Us | Capabilities | Casting Design | Cost Savings Ideas | Automotive Castings | Quality | FREE Die Cast Guide | Contact

Cost Savings Ideas

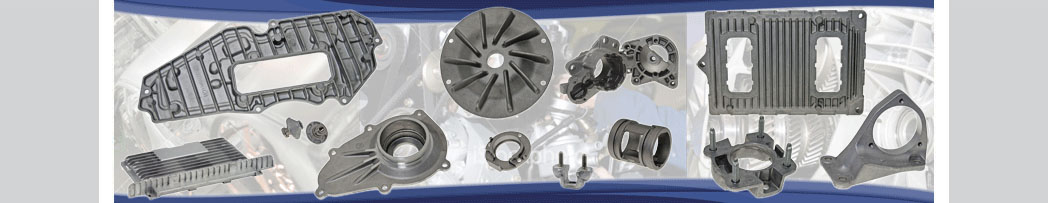

Optimize Design for Castability and Cost Savings:

Helpful Design Basics:

- The Basic wall section recommended for A380 /A383 Alloy is 2.5mm/3.0mm for most castings

- Draft angels should be no less than 1.5-2.0 degrees per side (3.0 Degrees per side is preferable)

- Try to avoid thin Tool Steel Conditions that will promote excessive soldering, and early die fatigue.

- Try to avoid blind spots (Bosses with no ribs for feeding)

- Minimum of 1.5mm fillets and corner radii’s where permissible

- Add ribbing for strength and feeding characteristics

- Try to avoid large wall thickness increases (Maintaining a Uniform Casting Wall Section is crucial

for controlling both types of porosity and filling related defects)

- Gasket Seal Grooves should have adequate draft (2-3 degrees per side) considerations

for maintaining desired net shape (This will aide in preventing drag, and reduce the need

for expensive machining processes)

- Use a practical approach for GD&T Requirements (Work with all mating parts for Feasibility

of Fit Form and Function. This will have a huge impact on cost and quality constraints)

- Allow adequate surface area on casting for proper Ejection (Ejector Pin Placement)

- Design Parting Lines that have gradual transitions, and have a minimum draft angel of

5 Degrees Per Side. (7-10 degree draft is preferred)

- Consideration for Gating the casting should be at the forefront of discussion when

designing the casting (Tech Review Meetings are essential for finding solutions,

and optimizing the casting design)

Home | About Us | Capabilities | Casting Design | Cost Savings Ideas | Automotive Castings | Quality

Die Casting Equipment and Tonnage | Request for Quote | FREE Die Cast Guide | Contact