Home | About Us | Capabilities | Casting Design | Cost Savings Ideas | Automotive Castings | Quality | FREE DIE CAST GUIDE | Contact

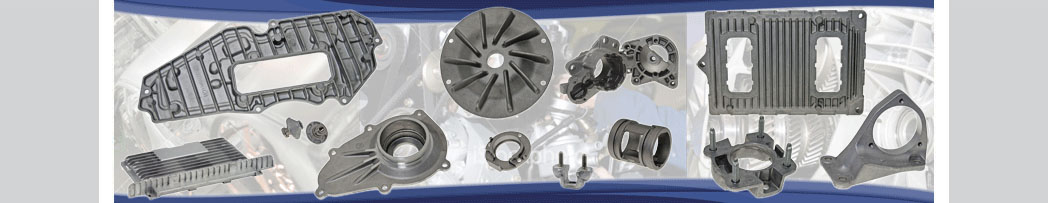

Automotive Castings

Key Industries . . .

• Electronic Heat Sink Control Modules

• Electronic Power Steering Components

• Variable Valve Timing

• Engine and Transmission Mount

Electronic Heat Sink Control Module Castings:

Photo 1: Cover Control Module / Heat Sink casting for Automated-Manual Dual Clutch Transmission (DCT)

Photo 2: Housing for Electronic Engine Control Module (Heat Sink)

Photo 3: Cover for Electronic Control Module for Engine and Transmission Electronics (Heat Sink)

Yoder Industries, Inc., specializes in high technology castings, including difficult to cast engine

and transmission heat sink die castings. These precision engineered electronic control modules require

a synergy of optimized casting design and critically controlled casting parameters to ensure consistency

in casting quality. While the fin geometry is critical to heat dissipation and meeting customer FEA

requirements, the elements of the optimized casting design and die cast process are at the heart

of success. Utilizing state of the art process monitoring and process control techniques, Yoder is

able to achieve exception casting integrity and surface finish. Yoder Industries is pleased to supply

European and U.S. automotive customers with a variety of heat sink control modules.

Key Features:

- Casting to net shape no machining required

- Zero Heat Check permitted on DCT castings without machining

- Surface Finish and Surface Tension different on opposite sides of casting

- Excellent fill of fins

- Critical flatness

- Cleanliness requirements

- Packaging concept developed by Yoder Industries

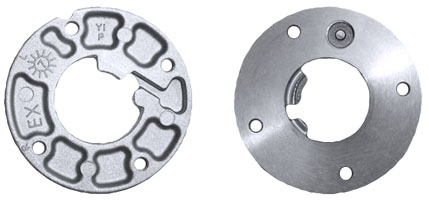

Electronic Power Steering Components:

Photo 1: Half Shaft Power Steering Bracket Hanger (Intermediate Drive Shaft)

Photo 2: Half Shaft Power Steering Flange (Intermediate Drive Shaft)

Photo 3: Electronic Power Steering Housing

Photo 4: Electronic Power Steering Cover Assist

Yoder Industries, Inc. specializes in new technology castings, including electronic

power steering components. With a focus on EPS, drive shaft and assist castings.

Due to stringent requirements for porosity and surface finish, these components require Robust

casting designs and repeatability in the manufacturing process. We provide precision machined

castings to tight tolerance requirements.

Yoder Industries is the leading U.S. supplier of intake and

exhaust castings for Variable Valve Timing assemblies.

Behind fuel efficiency and the smooth ride of the VVT technology, is a die casting that has exceeded

customer expectations.

Yoder Industries is maintaining a casting flatness average of .161 or less and as a result,

machining flatness of up to 18 microns or 0.0007” is achieved and Zero porosity.

- Yoder Industries is a WORLDWIDE INDUSTRY LEADER in providing uniquely developed

and proved methods for casting steel threaded studs and inserts into castings. - Core Business for Yoder Industries, Inc.

- Expertise in unique bolt design for castability.

- Proven methods for tool cavity design and insert design ensuring 100% FLASH FREE threads

through our VisiTech System. - With high-tech precision, steel and bronze bearings are also accurately cast into place.

- This method and customized process substantially saves costs over pressing inserts in place.

Automotive Applications

Over 25 Years supplying 2nd Tier

- Automotive Products with cast-in-place insert technology

- Engine mounts

- Hydro mounts

- Transmission mounts

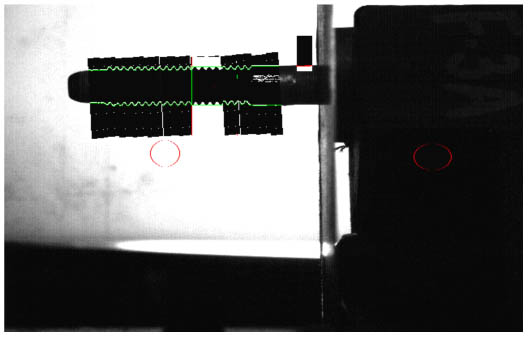

Yoder VisTech System

100% AUTOMATED VISION INSPECTION

- 100% Verifed AUTOMATED Vision Inspection for insert cast parts.

- Zero Defects to our Customers

- Customed designed and built Yoder Industries technology especially for

"cast-in-place" insert castings. - Verifying the insert from our supplier is 100% conforming.

- Verifying the casting with the insert(s) are 100% conforming.

Camera Detection Criteria

Automated cameras can detect unlimited defects:

To name a few . . .

- Flash on the threaded insert (top)

- Flash on the threaded insert (bottom)

- Bolt missing

- Trim damage around part

- Incorrect threaded bolt

- Bolt missing threads

Additional Features

- Yoder VisTech System cameras can accommodate castings

with unique characteristics:- 2 similar threaded bolts

- 2 dissimilar inserts- bolt and a pin Insert-CAST

Home | About Us | Capabilities | Casting Design | Cost Savings Ideas | Automotive Castings | Quality

Die Casting Equipment and Tonnage | Request for Quote | FREE Die Cast Guide | Contact